Basic Guide To Chimney Cowls

Types, What They Do & Materials Used

Basic Guide To Chimney Cowls – Types, What They Do & Materials Used.

A chimney cowl is an important part of your chimney system. It serves as a cap and prevents rain, snow, and animals from getting into the chimney. In this blog post, we will discuss the different types of cowls, what they do, and the materials used to make them. We will also provide some tips on how to choose the right cowl for your needs.

What is a chimney cowl?

A chimney cowl is a cap or covering that is placed over the top of a chimney. Cowls are used to keep out rain, snow, and animals, and to help direct the flow of smoke up and out of the chimney. There are many different types of cowls available on the market which we will go through below. Finally, cowls help to direct the flow of smoke up and out of the chimney, making it more efficient.

What do chimney cowls do?

Chimney cowls serve several important functions. Firstly, they keep water and moisture out of the chimney system which can cause rusting and deterioration of the structure. Secondly, they prevent animals from getting into the chimney and nesting there. This can be a fire hazard as well as an annoyance.

There are 9 basic types of chimney cowl available on the Irish and British markets.

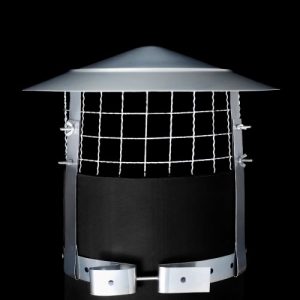

1. Anti Bird / Anti Rain Chimney Cowl

This is a chimney cowl with a hat to prevent rainwater entering the chimney and a mesh to prevent birds and other vermin entering the chimney. These chimney cowls can be produced from steel, aluminium, or stainless steel. When burning solid fuel, it is important that the mesh measures at least 1” square so that it does not clog up with soot and prevent smoke escaping and is constructed from stainless steel so that it does not disintegrate. Click here to view our range of Anti Bird / Anti RainChimney Cowls.

2. Pot Hanger Chimney Cowl

This chimney cowl is used when installing a flexible stainless-steel liner inside a chimney. The liner is connected to the bottom of the pot hanger cowl and the cowl is then attached to the chimney pot. Normally an Anti Bird / Anti Rain or Static Anti Downdraught design is used with a pot hanger chimney cowl. They are generally produced in Aluminium or Stainless Steel. Click here to view our range of Pot Hanger Chimney Cowls.

3. Static (no movement) Anti Downdraught Chimney Cowl

These are chimney cowls that have been designed so that they help shield the chimney from wind penetration while allowing fumes to escape unhindered. Important that these chimney cowls have been laboratory tested. Most variants incorporate a rain guard. These chimney cowls offer moderate protection from wind penetration and are generally trouble free as they have no moving parts to break down. Some products can help improve the draught where there is a lack of draught in the chimney. They are generally produced in Aluminium or Stainless Steel. Click here to view our range Static Anti Downdraught Chimney Cowls.

4. Revolving Anti Downdraught Chimney Cowl

Also known as a Spinner Anti Downdraught Chimney Cowl. This chimney cowl looks like a spinning globe with a series of fins catching the wind causing it to spin. A “Spinner” offers the best protection from wind penetration of the chimney and moderate rain protection. These chimney cowls need to be situated at least 18 feet or 5.5m from the stove or fireplace, otherwise the heat can dry the grease used in the bearings which allows it to revolve. They are generally produced in stainless steel, however, there are some variants manufactured from aluminium.

Click here to view our range of Spinner Anti Downdraught Chimney Cowls.

5. Electrical Chimney Cowl

This chimney cowl is driven by electricity and has a motor and impellor. An electrical chimney cowl is designed to create suction at the top of the flue and is generally used to create a draught in a chimney where there is a lack of draught or where the draught is insufficient. Electrical chimney cowls can also be used to prevent a downdraught. They are usually produced from cast aluminium and can be quite expensive. These chimney cowls need to be situated at least 18 feet or 5.5m from the stove or fireplace, otherwise the heat can dry the grease used in the bearings which allow it to revolve.

Click here to view our range of Electrical Fan Chimney Cowls.

6. Chimney Damper

This chimney product is designed to open and close the top of chimney from inside the dwelling. Generally, they can only be used with an open fire as there is a chain or steel rope used to operate the product from the fireplace. A damper is used to prevent heat loss when a fireplace is not being used. They can also prevent noise, rain, animals such as birds and wind entering the chimney when closed. Some variants allow the user to partially open or close the damper in a few positions meaning that draught or speed at which fuel burns in the fire can be regulated through use of the chain. Can also be used to prevent smoke entering a chimney that is not in use. Normally produced in stainless steel.

Click here to view our Chimney Damper.

7. Chimney Capper

A chimney capper is used to close a chimney pot that is not being used. They are generally produced from plastic, mild / galvanised steel, or aluminium.

8. Draught Restrictor

These are used to reduce the rate at which flue gases escape from the chimney – they are fitted when there is excessive draught from a stove or chimney. Can be produced in steel, aluminium, or stainless steel. They need to be cleaned regularly as they can soot-up rapidly.

Click here to view our Draught Restrictor.

9. Bird / Crow / Jackdaw Guard

This is a simple unit comprising of a series of sprung rods that are welded together to create an up-side-down wire funnel which is then inserted into the top of a chimney pot. Designed to stop birds from entering the chimney. Some designs incorporate a rain hat. Normally produced from painted mild or galvanised steel. This is a very inexpensive product.

Click here to view our Crow Guard.

Types Of Materials Used To Manufacture A Chimney Cowl.

There are generally 3 types of material used to manufacture chimney cowls and chimney terminals.

- Galvanised steel – cheapest material used and can rust or disintegrate relatively quickly. Little or no resistance to the acid contained in smoke. The least robust material used to manufacture chimney cowls and terminals. Not advisable to purchase a chimney cowl produced from it.

- Aluminium – Popular material as it will not rust and almost as inexpensive as galvanised steel, however, it is not suitable for high temperatures as it will soften and melt at temperatures of approx. 600 ° C. Difficult to weld aluminium so chimney cowls produced from this material are screwed or riveted together which can cause problems in freeze and thaw situations. Considered relatively robust.

- Stainless steel – Also a popular material as it will not rust but more expensive than the other two materials. Chimney cowls produced from stainless steel suitable for high temperatures, have good resistance to acid contained in smoke and are considered the most robust material to produce chimney cowls and terminals. In our opinion the best material to use.

Does my chimney need a cowl?

If you have a chimney, it is likely that you will need a cowl. Cowls are an important part of keeping your chimney system functioning properly and safe from the elements. When choosing a cowl, be sure to consider the type of material that it is made from as well as the size and shape of your chimney.

If you are unsure whether or not your chimney needs a cowl, consult a professional. They will be able to assess your system and recommend the right cowl for your needs.

Thank you for reading our blog post on Chimney Cowls! We hope you found it helpful. If you have any questions, get in touch. We are the leading distributors oif chimney cowls.